hardness test of pipe|hardness testing for aluminum : importing The so-called pipe fittings’ hardness is the ability of a material to resist the pressing of a harder material into its surface.According to different test methods and adaptation range,pipe fittings’ hardness has different units,brinell hardness is one of them. Pipe fittings’ hardness test is one of the most important indicators for . The Salinas-Blanco clinic (formerly named Pinnacle Healthcare) is conveniently located in the South Salinas between the 101 Freeway and Route 68. Our clinic specializes in the evaluation and treatment of work .

{plog:ftitle_list}

Veja o elenco de Brasil em 2025 na ESPN (BR). Inclui detalh.

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. The Brinell Hardness Test method is the .Date:2024-10-14 View:34 Tags:stainless steel seamless pipe hardness test method, smls ss pipe hardness test method. When conducting hardness testing on stainless steel, it is essential to consider the mechanical properties of stainless steel seamless pipes, which affect the material's performance during processes like deformation, stamping, and . Especially, our company’s latest development, the portable surface Rockwell hardness tester and pipe Rockwell hardness tester, can perform rapid and accurate hardness testing on stainless steel plates and . Pipe Stiffness. Pipe stifness testing is carried in accordance with ASTM D2412. At 10 percent deflection there should be no visual indication of cracking or structrual damage. . Standard Test Method for Indentation .

The so-called pipe fittings’ hardness is the ability of a material to resist the pressing of a harder material into its surface.According to different test methods and adaptation range,pipe fittings’ hardness has different units,brinell hardness is one of them. Pipe fittings’ hardness test is one of the most important indicators for .Test Methods Tolerances on pipe diameters, wall thickness, out-of-roundness Common defects . • CVN impact test • DWT test • Hardness test • Pipe markings and end colors Etc. Traceability. For PSL1 pipe, manufacturer shall establish and follow documented procedures to maintain a. The heat identity until all related chemical tests are . While a hardness test takes just a minute or so on one machine, the MYS, UTS, and elongation tests require sample preparation and a substantial investment in large-scale laboratory equipment. As a comparison, think in terms of seconds for a hardness test by a tube mill operator and hours for a tensile test by a dedicated metallurgy technician .The governing standard for the Barcol hardness test is ASTM D 2583. [4] Barcol hardness is measured on a scale from 0 to 100 with the typical range being between 50B and 90B. A measurement of 60B is roughly equivalent to a Shore hardness of 80D or .

When hardness testing of welds, a series of measurements are made in a given pattern at a specific distance from the sample edge or top of the weld. The progression of the hardness values can then be plotted in a graph. Methods typically used: HV5 and HV10 ; Applicable standards: ISO 9015-1/-2 ;The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten . Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition . Seamless steel pipe inside diameter of 6.0mm or more, a wall thickness of 13mm below the annealed seamless steel pipe, you can use a W-B75 type Wechsler hardness tester, which test is very fast, easy, and suitable for seamless steel pipe to do a quick and non-destructive qualification test. Seamless steel pipe inner diameter greater than 30mm .

RE: Hardness Test - How many readings should be performed per welded pipe diameter? weldstan (Materials) 16 Nov 15 18:42 There is no requirement in B31.1 or ASME I. Hardness locations and number of tests per location are requirements of the Owner, Engineer and even the Constructor. The hardness test of seamless steel pipe should take into account its mechanical properties, which is related to the performance and quality of deformation, stamping, cutting and other processing using stainless steel or carbon steel as raw materials. Therefore, all seamless steel pipes are subject to mechanical properties testing. There are two main types of .

The Vickers hardness test operates on similar principles to the Brinell test, the major difference being the use of a square based pyramidal diamond indentor rather than a hardened steel ball. . Performing hardness testing on cylindrical surfaces eg pipes and tubes, the radius of curvature will affect the indentation shape and can lead to .Project Staff/Test Technician Qualification Requirements 10. Pipe Sample Size and Lower Bound Hardness Statistical Estimates 11. Hardness Test Locations on Pipe 12. Pipe Surface Preparation 13. Testing Calibration, In-Process Evaluation, and Uncertainty 14. Field Hardness Data Evaluations 15. Hardness Conversion to Yield Strength 16. Hardness .Hardness testing of newly coated cutbacks at pipe joints is often performed prior to burying pipe, to reduce the chance of coating damage during the backfilling process. Solvent rub is another method for gauging the cure of a coating or . The Equotip 550 metal hardness tester is a versatile portable hardness testing solution using the Leeb rebound technique invented by Proceq. Top. Workspace EN English; Deutsch . Hardness testing of casts, flanges, .

The Charpy impact test is used to determine the toughness of a welded joint and to compare the toughness of different welding processes. 5. NICK-BREAK TEST FOR WELD TESTING. This test is applied to a welded butt joint in a plate or pipe to check weld soundness. The typical specimen dimensions for plate and pipe. Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .Advanced Ultrasonic Hardness Tester UCI 3000 applies ultrasonic contact impedance method to do comparative hardness measurement for testing pieces, with the high accuracy, efficiency, portability, and easy operation. UCI 3000 is a high-precision portable device for quick measuring hardness of small fogging, cast material, weld inspection, heat affected zone, Ion-nitride .

Portable Hardness Testers are ideal hardness testing tools where large samples, which cannot be easily transported to a traditional tabletop hardness tester, or specimens with hard-to-access areas are to be tested. . Pipe Testing. Contact Qualitest. Phone: 1 . Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is . Hardness Test on pipe with HARDTEST II AFFRI

Barcol Hardness is used to determine the hardness of both reinforced and non-reinforced rigid plastics. Test Procedure: The specimen is placed under the indentor of the Barcol hardness tester and a uniform pressure is applied to the specimen until the dial indication reaches a maximum. The depth of the penetration is converted into absolute .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .PDF | On Jan 1, 2022, K. Mansouri and others published Vickers Hardness Test of Steel Pipes Welded by High Frequency Induction | Find, read and cite all the research you need on ResearchGateIn application, hardness testing will determine how well a steel pipe will hold up over time and how long it can be used effectively without it breaking. Residual Stress Measurement It goes without saying that stress and fatigue cause cracks and fractures all over piping material, especially during the same point time when both stress and .

multiple comparisons using multcomp package t test

what is hardness testing

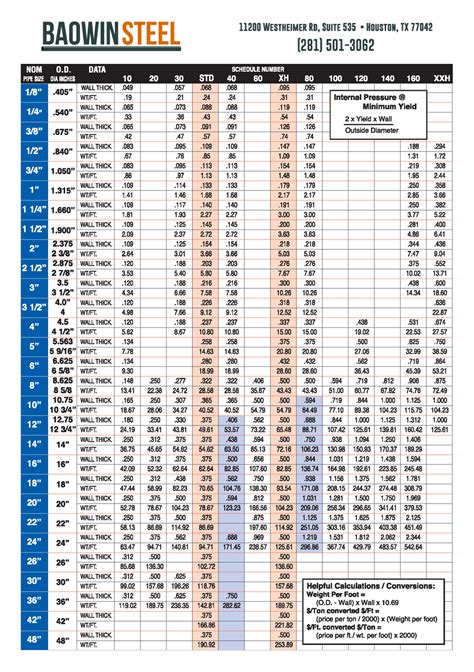

pipe hardness chart

industrial hardness testing

Exibindo 10 de 2653 reclamações (referente ao filtro selecion.

hardness test of pipe|hardness testing for aluminum